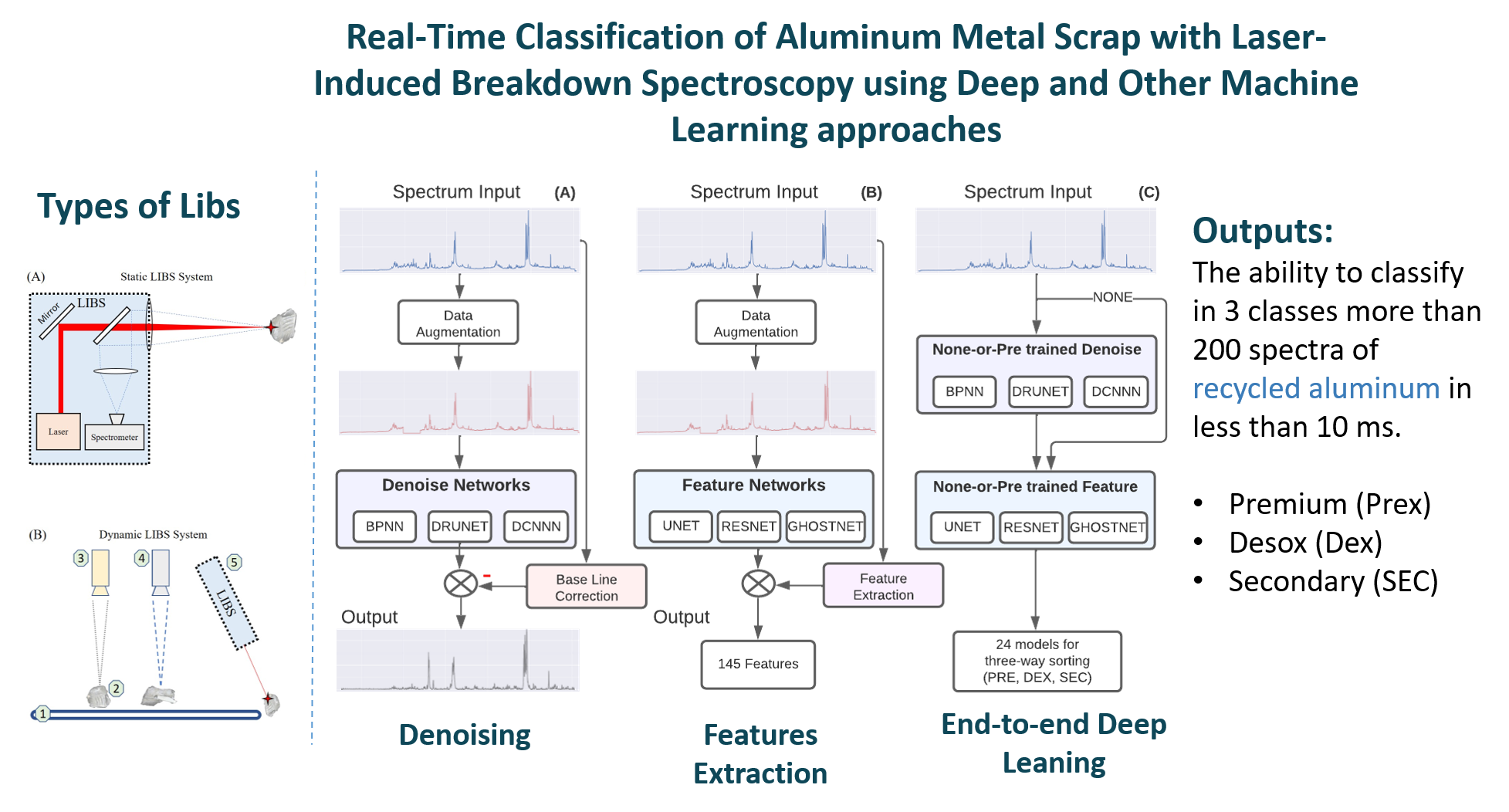

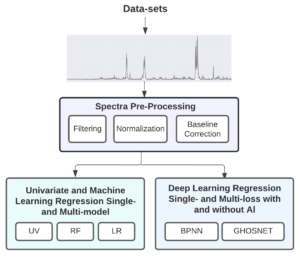

In this study, the use of Laser-Induced Breakdown Spectroscopy (LIBS), Machine Learning (ML), and Deep Learning (DL) for the three-way sorting of Aluminum (Al) is proposed. Two sample sets of Al scrap are used: one containing 733 pieces for pre-training and validation with a ground truth of X-Ray Fluorescence (XRF), and the second containing 210 pieces for testing for unknown compositions. The proposed method comprises a denoising system combined with a method that extracts 145 features from the raw LIBS spectra. Further, three ML algorithms are assessed to identify the best-performing one to classify unknown pieces of aluminum post-consumer scrap into three commercially interesting output classes. The classified pieces are weighed, melted, and analyzed using spark analysis. Finally, to optimize the best-performing ML system, three state-of-the-art denoising and three feature extraction networks are pre-trained for learning the baseline correction and the proposed feature extraction.